Your session has timed out. Please log in again

SPEEDIO

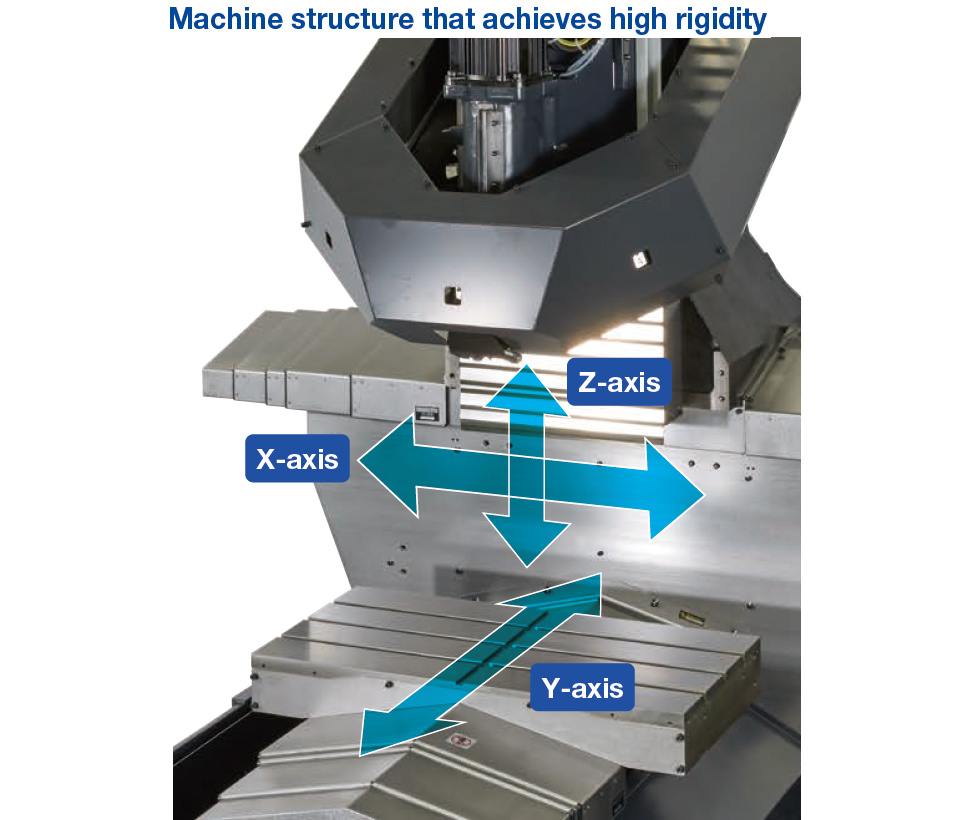

The machine structure has been reviewed from the basics, utilizing structural analysis techniques. Using optimal element components has enabled the machine to feature the highest rigidity in the SPEEDIO Series.

・Machine structure The highest rigidity ever has been achieved by moving the table only by the Y-axis and using column movement for the X- and Z-axes, and reducing the spindle head overhang

・Highly rigid spindle Spindle bearings larger than those of other models are used to improve spindle rigidity.

・Highly rigid guide Larger guides are used to improve the guide rigidity of each axis.

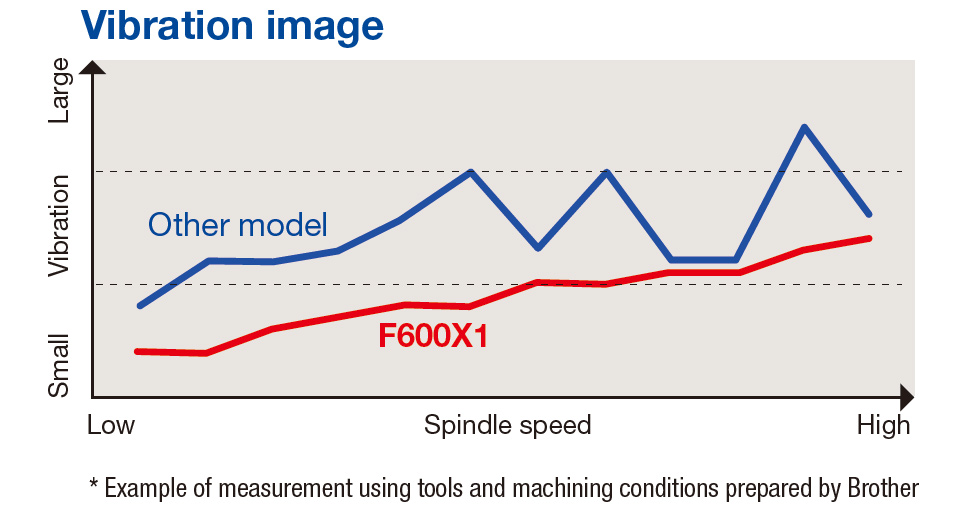

Minimizing vibration makes it possible to set a wide range of machining conditions, enabling machining under higher conditions. This leads to a reduction in achining time.

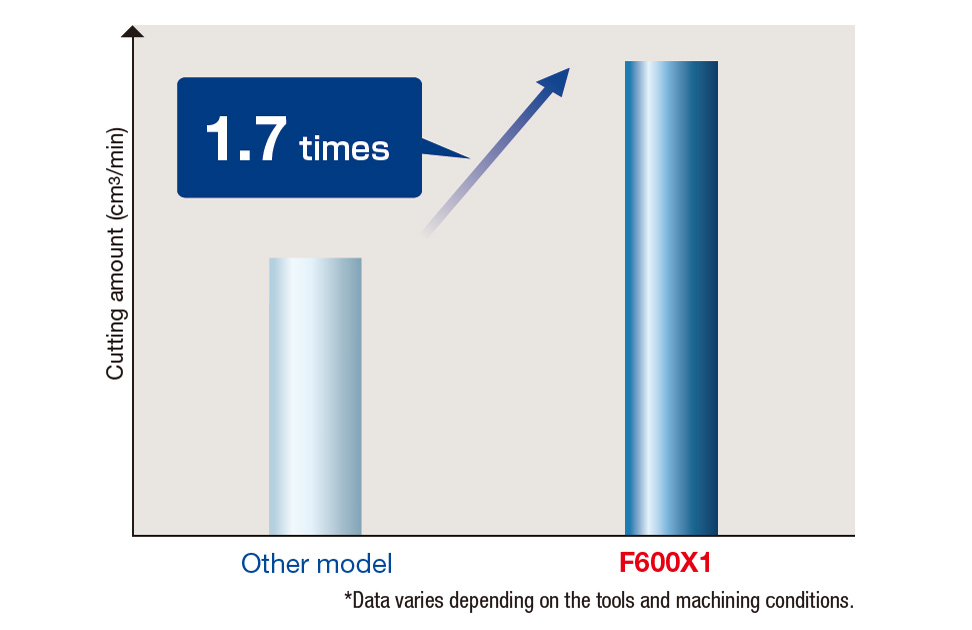

Cutting amount has significantly increased.

・Machining example : End mill ø16, Workpiece : Carbon steel

The highest class high-torque motor among spindle motors used for #30 spindle machines is standard equipped.

| Spindle motor characteristics |

|---|

|

Fastest tool change has been achieved by optimizing and increasing the speed of the spindle start/stop, Z-axis up/down, and magazine operation.

| 22- tool magazine |

|---|

|

| 14- tool magazine |

|---|

|

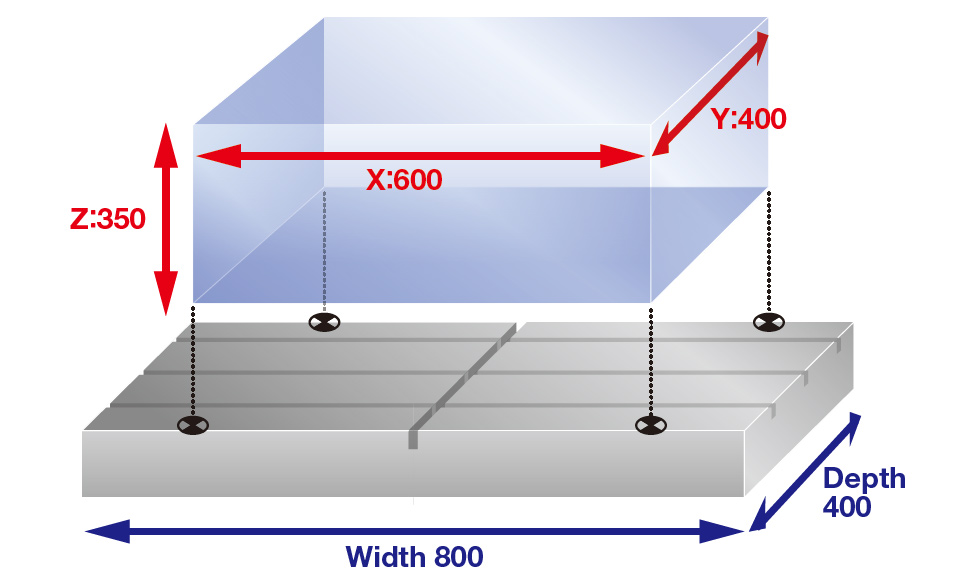

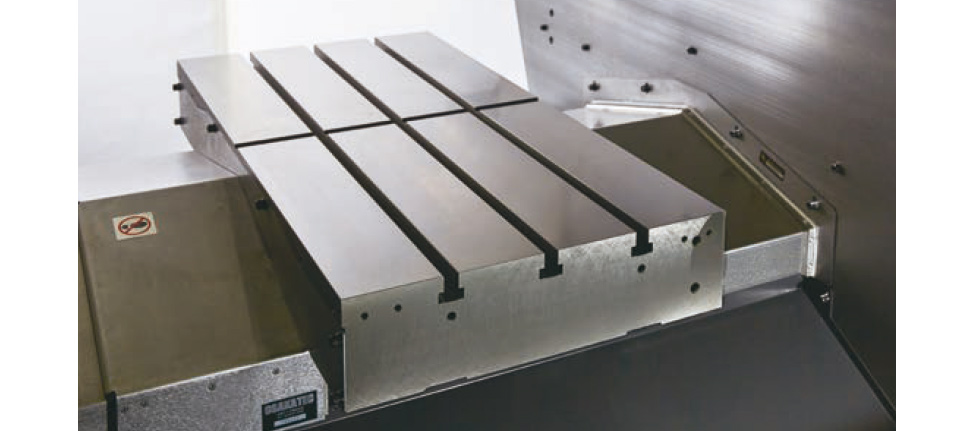

Size and loading capacity equivalent to high-end models.

|

As the structure below the table has been simplified due to the axes configuration, the table thickness was increased to improve rigidity. A maximum loading capacity of 500 kg has been achieved, and table deformation minimized.

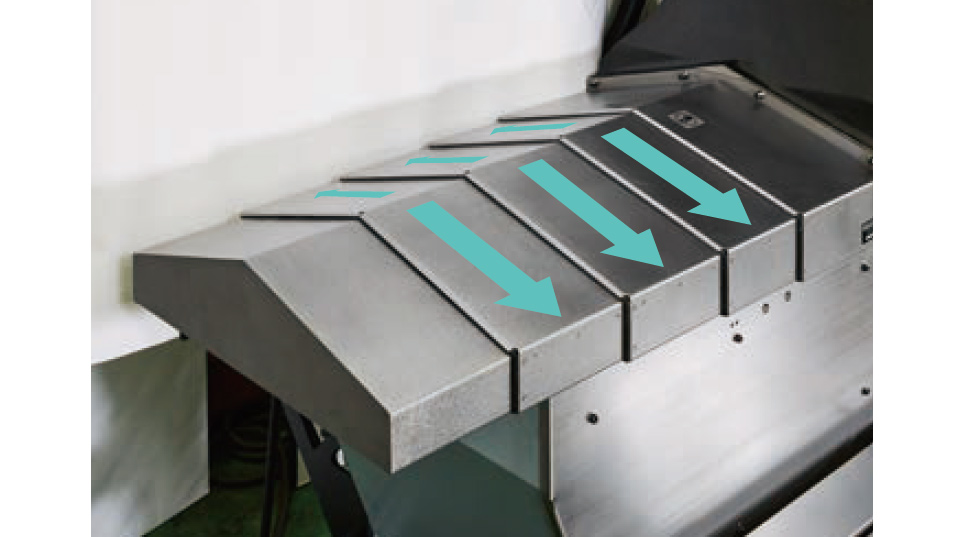

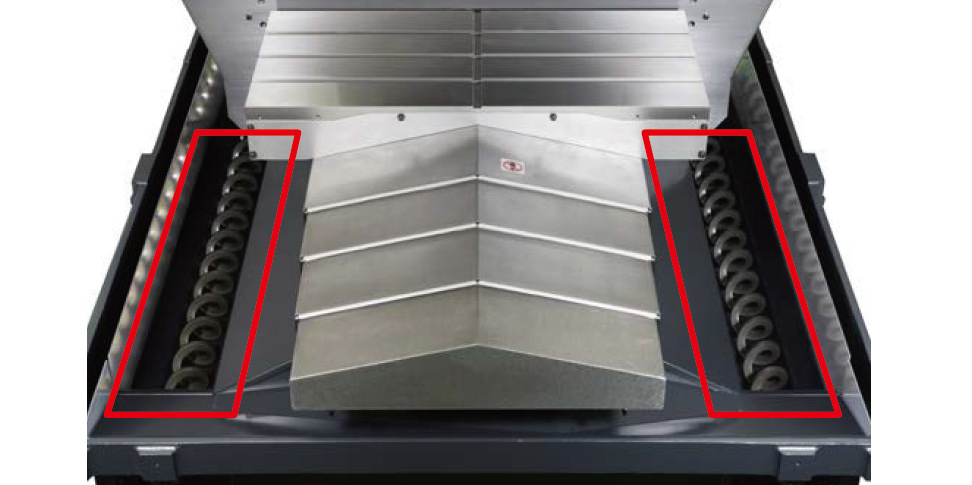

Chip discharge performance has been improved along with the expansion of the machining area. In addition, the machine is equipped with a variety of functions, such as air-assisted tool washing, to improve reliability.

Roof-shape telescopic covers are used for the X- and Y-axes to discharge chips rapidly.

Long and difficult-to-flow chips can be discharged smoothly, and steel chips can also be discharged reliably, avoiding accumulation.

Equipped with tool monitoring functions ・ATC monitoring ・High-accuracy mode BII (read-ahead 200 blocks) ・Motor insulation resistance measurement function ・Waveform output to memory card ・PLC function

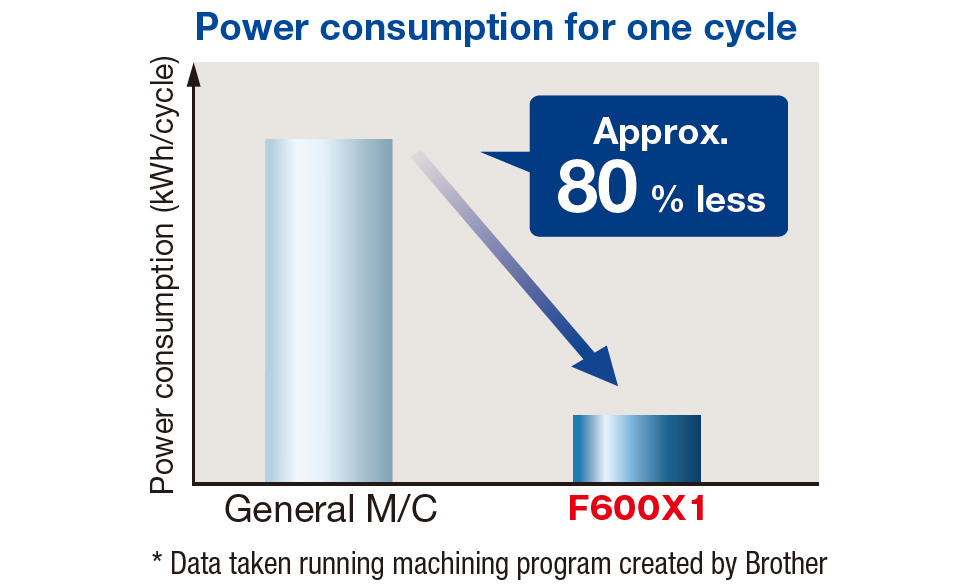

In addition to low power and air consumption, the machine is equipped with a power regeneration system and a variety of energy saving functions, achieving high environmental performance.

|

|

|

|

|

|---|---|---|---|---|

| S300X1/S500X1/S700X1 | S1000X1 | M140X1 | R450X1 | R650X1 |

|

|

|

|

|

|

|

|---|

| TC-32BN QT/FT |

|

|