How to Select the Right Garment

The final appearance and feel of a garment print is heavily influenced by the choices made long before printing begins. If you’re looking for something to print upon, you want to find cotton clothing material that best compliments your printing setup and workflow. Keep these six important things in mind when selecting a garment for printing.

The Six Sides of Garment Selection

- Yarn

- Smoothing

- Fibers

- Finish

- Diameter

- Pretreating

A Deeper Look at the Six Sides of Garment Selection

A Deeper Look at the Six Sides of Garment Selection

YARN: Find out what kind of yarn is used to make your garment

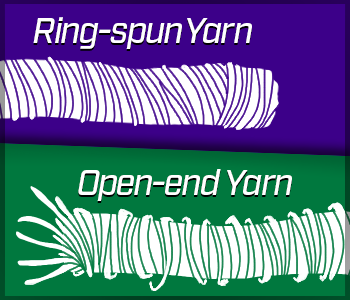

When you’re starting out, finding the right type of yarn can be a little challenging. There are two types of yarn that are commonly used for cotton apparel – ring spun and open end yarn. Ring spun yarn is made by continuously twisting and thinning cotton strands with a spindle.Open end yarn on the other hand is collectively twisted without using a spindle. Ring spun makes for a smoother base to print on and allows for a crisper DTG print. Ring spun is made to be tighter, but costs more. Open end is a cheaper option with more texture.

SMOOTHING: What smoothing method is used on your yarn?

Yarn can be made much smoother in a variety of ways. Check its makeup for either combing or carding techniques. Combing, much like with hair, takes the tiny threads of yarn and straightens them out while removing broken pieces. Carding tries to even the threads out on the surface without removing the broken pieces. Garments that are combined help to minimize the fibers sticking up.

If you look closely at a cotton garment, you will see little strands of yarn sticking up. We call these strands "fibers". The process of fibers sticking up is called "fibrillation". When searching for garments, look for ones that have as little fibrillation as possible. Less fibrillation in the beginning = more potential for a smoother print.

Watch fibrillation strategies video

FINISH: What to do about the finish of your garment

People who manufacture fabrics want to find the best way to make garments that are flatter and softer to the touch. Because of this, they may integrate some type of product into your garment – silicon for a softer feeling, or starch for tighter yarn to name a few. We recommend doing a wash test for these types of garments to make sure that DTG printer ink can fully adhere to the fabrics.

DIAMETER: What is the diameter of the yarn used in the garment?

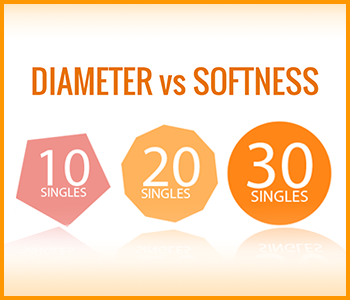

Garments are typically offered in 18, 20, and 30 singles. The higher the number, the finer the thread and ultimately the softer feel. Fabrics of different diameter can react differently to the inks of a DTG printer. Doing a wash test can help determine how well your garments will hold up from printed ink.

PRETREATING: How does your fabric react to pretreatments?

Pretreatment helps establish an even base layer for white underbase and brings out the vibrancy of inks on dark garments. However, pretreat on the wrong garment can cause discoloration due to a reaction with the dyes used. Make sure you know whether or not your garment was originally manufactured with non-reactive dyes. If you want to print on any polyester material, be careful of the effects of dye migration. Upon curing, ink dyes from polyester garments can mix with the white underbase of the print, leading to discoloration.