Get the Story on Brother DTG from Industry Experts – Our Customers

Brother DTG’s history of customer support is bookmarked with focused efforts to help our customers. Through Brother products and service, we help screen printers, embroidery shops, apparel brands, fashion designers and other businesses build market share and expand their product offerings. With our GT-541 printer in 2005, we offered installation services by an authorized technician. We have improved our services over time, and provided new avenues of resources, including technical support, and online guides. With our most recent GTX and GTX pro machines, we now offer Brother Academy, an online resource that helps users learn everything they need to know about operating and maintaining their DTG equipment.

Helpful Advice and Favorite Features from our Brother DTG Customers

Our customers define their method of success in part by harnessing the power of Brother DTG printers. Hear how Brother DTG has helped them on their journey.

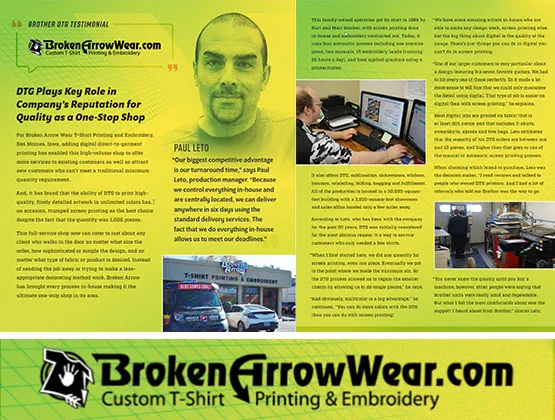

Broken Arrow

“Our biggest competitive advantage is our turnaround time…because we control everything in-house and are centrally located, we can deliver anywhere in six days using the standard delivery services. The fact that we do everything in-house allows us to meet our deadlines."

- Paul Leto – Broken Arrow Wear T-Shirt Printing and Embroidery

T-Shirt Palace

“From our previous experience and the struggles that we had, we learned it is very important to partner with the right company that will have a major impact on the success of your business. The quality that brother gives on these machines allow us to deliver a high quality vibrant design exactly how it’s shown on the internet to the customer.”

- Jermy Katty – Vice President, Operations and Development at Tee Shirt Palace

Inkpressions

“When we first decided to add digital direct-to-garment equipment, we tested a range of printers, and Brother was right at the top of the list. We knew we needed a production-oriented solution. We were not looking to just print a few shirts or batch jobs. We also wanted a solution that was scalable and could be expanded to grow with our business.”

- Joe Chase of Inkpressions

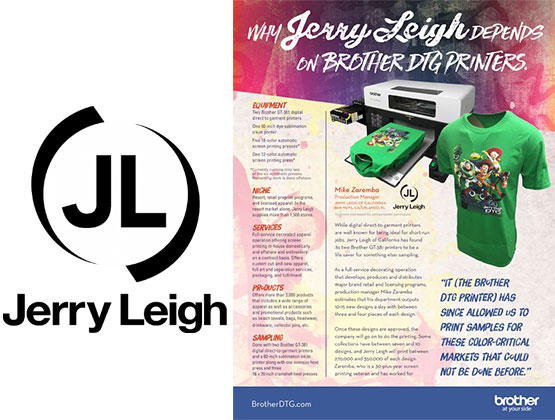

Jerry Leigh

“If I have to do production sampling for a big box discount retailer, there is no benefit to using screen printing. During the first sales pitch, they may be showing 70 graphics that will be whittled down to 20 winners. By using the Brother GT-381 to make the production samples, I am saving on the time and money it would cost to make the screens for 50 designs. It is a huge savings.”

- Mike Zaremba – Production Manager at Jerry Leigh of California

American Apparel

“The Brother digital garment printers give us the ability to quickly move from one project to another without changing screens. It is an advantage. We do not have costly set-up times or delivery disruptions with the Brother machines.” - Marty Bailey, Chief Manufacturing Officer at American Apparel

Cafe Press

“During the month of December, one Brother GT-541 printer will generate upwards of 3,300 print-on-demand products in a single week, and with tens of thousands of orders coming in every day.” - Chris Freeman, Director of Engineering at CafePress

ntice

“The Brother GT-3 Series printer has provided my firm with the ability to produce dark shirts in an easy, economical manner with fast turnaround and create intricate and vibrant designs that are less costly than using the screen printing method.” - Andrew and Tammy Preston, Owners of North Texas Ink and Embroidery

WOW

"We’ve found that our customers are much happier producing shirts digitally on the GT-3 Series than on silk screening because digital lays down less ink. Customers say they can breathe in their shirts. They don’t feel like they have a large amount of ink across the front of their chest.” - Tim and Kathy Hughes, Owners of WOW Image Group

Success Through Upkeep

To keep their printers running smoothly, diligent customers take the time to perform routine maintenance. See how Brother customers benefit from taking proper care of their garment printers.

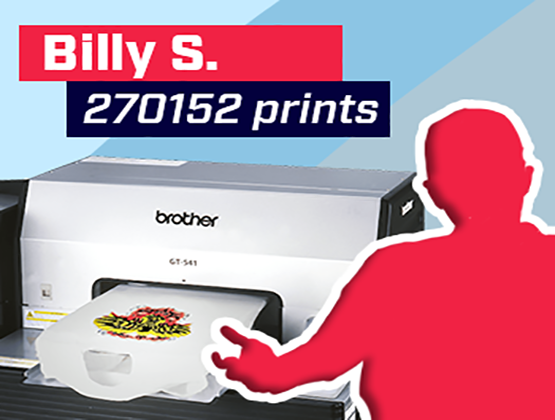

Billy S. Cummings, GA

“We bought this printer (GT-541) brand new in 2009, and 270,000 prints later she is still working like a charm every single day. We have had a total of perhaps 3 days of downtime in 7 years when replacing heads, but that is all. I stand by this printer with full conviction and I would never use another brand for our company."

- Estimated Retail Price may vary.

- Features vary by model.