Your session has timed out. Please log in again

SPEEDIO

The QT (Quick Turn) table is Brother's original turn table type high-speed 2-face pallet changer. High-speed pallet change is enabled by avoiding lift-up operation while achieving high reliability through a sealed structure. Workpieces on one pallet can be changed while machining workpieces on the other pallet. Therefore, waste in workpiece change time is eliminated, enabling nonstop machining.

| Pallet change time |

|---|

| 3.4s |

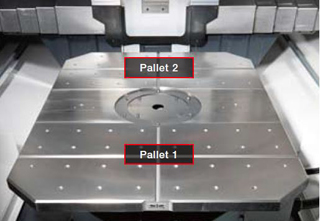

Making use of our original pallet changer technologies that have been installed on over 15,000 units, the machine provides sufficient travels and a large jig area, which are not available on conventional #30 machines standard equipped with a pallet changer.

|

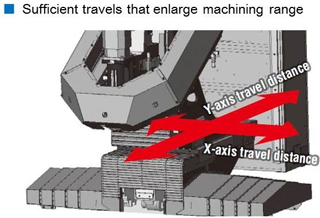

X-axis travel distance:650mm

Y-axis travel distance:400mm |

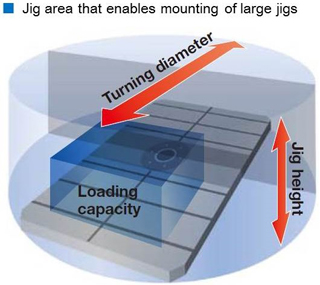

The turning diameter and the table size have been increased, enabling the mounting of large jigs. In particular, this makes mounting a trunnion jig using a rotary table easier.

|

Turning diameter:1,250mm

Jig height:350mm Leading capacity(one face):200kg Work area size(one face):800x400mm |

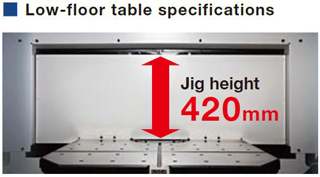

To enable the mounting of much larger jigs, two options are available: a low-floor table option that increases the jig height and a turning diameter enlargement option that increases the turning diameter to 1,300 mm. The loading capacity can also be increased to 300 kg (one face).

Enhanced speed and acceleration, and optimal control with any waste operation and time eliminated, drive machine performance to the fullest, demonstrating high productivity.

| Spindle start/stop time |

|---|

| 0.15s |

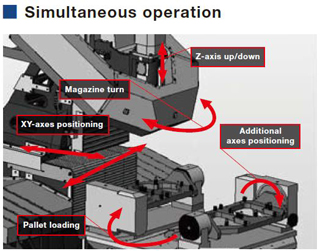

High-speed tool change is achieved by increasing the speed of, and optimizing the control for, spindle start/stop, Z-axis up/down, and magazine operation.

|

Tool change time

22-tool magazine(14-tool) |

|---|

|

Tool - Tool:0.9s(0.8s)

Chip - Chip:1.7s(1.6s) |

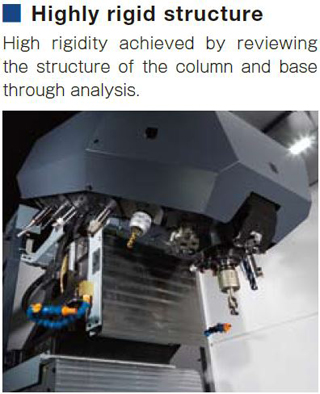

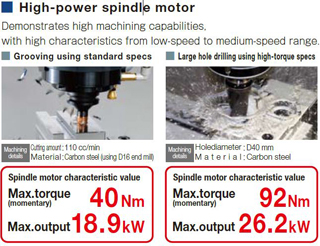

The highly rigid structure and a high-power spindle motor provide high-range machining capabilities from heavy-duty machining to high-speed high-efficiency machining.

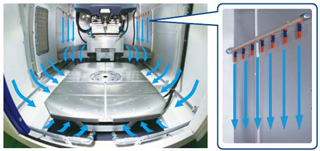

High reliability is achieved by improving chip discharge performance and enhancing maintenance functions, contributing to the improvement of the machine's operating rate.

Various energy saving functions, such as Power regeneration system, Energy saving pump, LED type work light and Highly efficient spindle motor reduce power consumption, achieving high environmental performance.

Distributors

- Inquiry & Purchase

- Repair & Service

Contact infomation for distributors in your area

Brother Global

Technical Center

Contact information for Brother Technical Centers in Europe and other areas

|

|

|

|

|

|---|---|---|---|---|

| S300X1/S500X1/S700X1 | S1000X1 | M140X1 | R450X1 | R650X1 |

|

|

|

|

|

|

|

|---|

| TC-32BN QT/FT |

|

|