Your session has timed out. Please log in again

SPEEDIO

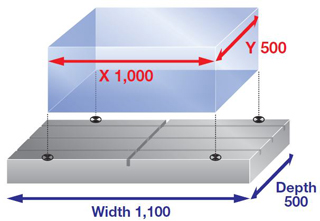

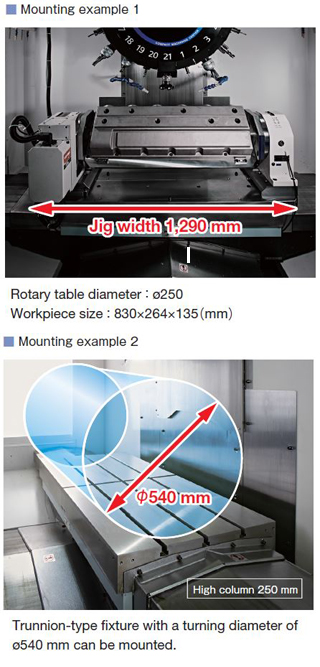

Increase in X- and Y-axes travels and expansion of the machining area have enabled large workpiece machining and large jig mounting, which were not possible on conventional #30 machines.

A wider, longer jig area has been secured, enabling mounting of large jigs. 150 mm, 250 mm, and 350 mm high columns (optional) are available to meet customers' needs.

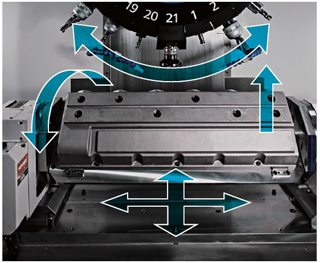

Wasted time has been further reduced by simultaneously performing tool change and positioning X/Y and additional axes.

Using a fast acceleration/deceleration spindle motor enables the spindle to start and stop in an extremely short time.

| Spindle start/stop time |

|---|

|

High-speed tool change has been achieved by optimizing and increasing the speed of spindle start/stop, Z-axis up/down, and magazine movement.

|

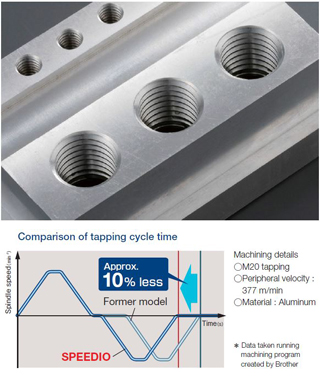

Delay in response has been reduced to almost zero by increasing the responsiveness of the servomotor. High-speed synchronized tapping at the fastest level in the world has been achieved.

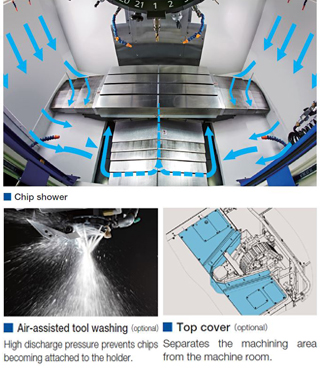

Chip discharge performance has been improved along with the expansion of the machining area. In addition, the machine is equipped with a variety of functions, such as air-assisted tool washing, to improve reliability.

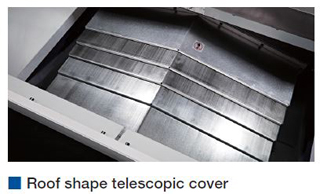

Roof shape telescopic covers are used for the X/Y-axes to quickly discharge chips from the machining area. Installing two chip shower pumps has doubled the flow rate.

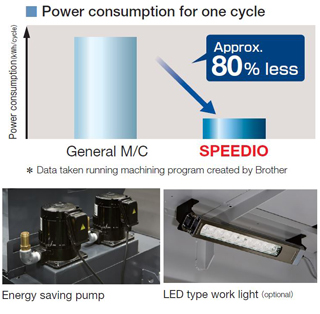

In addition to low power and air consumption, the machine is equipped with a power regeneration system and a variety of energy saving functions, achieving high environmental performance.

|

|

|

|

|

|---|---|---|---|---|

| S300X1/S500X1/S700X1 | S1000X1 | M140X1 | R450X1 | R650X1 |

|

|

|

|

|

|

|

|---|

| TC-32BN QT/FT |

|

|