Your session has timed out. Please log in again

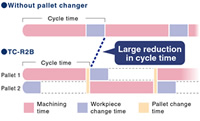

The QT (Quick Turn) table is Brother’s original pallet changer. It is a turn table type where two pallets turn at high speed. High-speed pallet change is achieved by the combination of a servomotor and a HRH gear. The enclosed structure ensures high reliability.

Using the QT table allows you to change workpieces on one pallet while machining workpieces on the other pallet. This eliminates waste in workpiece change time, enabling nonstop machining.

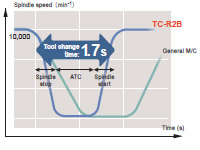

The machine is equipped with a magazine driven by an AC servomotor, enabling high-speed magazine turn. In addition to the adjacent tool, even the farthest tool can be changed in short time.

The high acceleration/deceleration spindle motor used enables the spindle to start or stop in short time. In particular, as the motor torque in the medium and high speed range is high, power is fully utilized for start and stop at high speed. This enables nonstop ATC where the tools are changed without stoppage of the Z-axis.

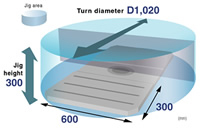

Improvements of the mechanical structure and the addition of a function where the column moves to a safe position as the QT table turns, have greatly increased jig areas and increased loading weight capacity.

A jig, such as an index table, can easily be loaded on to the machine thus allowing more freedom at your production site.

The machine is equipped with a B00 series CNC controller developed integrally with the machine, focusing on usability. Various userfriendly functions are available, such as the menu programming function, USB memory interface, and tool length range setting function. In addition to these, some new functions have been added, for example, the ATC column movement function to make tool change easier and the tap return function to assist tool recovery in the event of power failure.

Machine rigidity has been greatly improved by CAE analyzed, highly rigid column shape, expanded guide span, and using highly rigid guide.

In addition to high torque in the medium- and high-speed range (feature of Tapping Center), torque in the low-speed range is greatly improved. High cutting performance is realized.

Low power consumption is achieved by using a low-inertia spindle and a highly efficient motor to drive the spindle.

The structure of the spindle covering has been enhanced to reduce air purge. Air blast operations have also been reviewed to optimize the air discharge timing. These improvements have greatly reduced air consumption.

|

|

|

|---|---|---|

| TC-S2DN/-O/-S | TC-22B/TC-22B-O | TC-20B |

|

|

|

|

|

|

|

|---|---|---|

| TC-R2B | TC-32BN QT/FT | TC-31B |

|

|

|

|