Your session has timed out. Please log in again

TC-S2DN-O / TC-S2DN-S

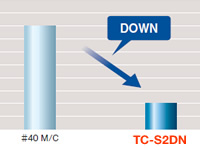

Tool change time has been greatly reduced to achieve high productivity.

Major machining details

The turning mechanism has been redesigned to greatly reduce the tool change time. The magazine is servomotor driven to achieve smooth turning.

The high acceleration/deceleration spindle motor used enables the spindle to start or stop in short time. Tool change can be completed without stopping the Z-axis.

Optimized structure and arrangement of ribs achieve higher machine rigidity.

Addition of high-torque specifications lead to high cutting performance.

The machine needs to be rigid to ensure high cutting ability. The shape of the base and column, and the arrangement of the ribs have been optimized through CAE analysis.

The improvement of various internal sections has achieved stable cutting performance that does not depend on the spindle speed.

High torque in the medium and high-speed range is one of the features of the TC's spindle motor. The new high-torque motor further enhances torque in the medium and high-speed range, and also greatly improves torque in the low-speed range. A wider variety of machining, including large hole drilling and tapping, is possible.

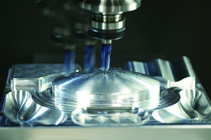

Improved tool rigidity reduces vibration during machining and tool tilt. In addition to this, air assisted tool washing prevents chips being caught between the tool and the spindle.

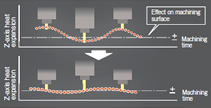

The sensorless heat expansion compensation system has been modified to include a function that compensates for biased heat expansion due to the influence of heat generated by the motor or depending on the axis moving position. More stable compensation ensured.

By our high speed spindle specification, the machine feed rate can be increased to further help improve machine productivity. Also, by using the High accuracy mode All. High speed 3D maching with high machining accuracy and surfacequality can be achieved.

Low power and air consumption greatly reduces CO2 emissions, creating an earth-friendly plant environment.

Low power consumption is achieved by using a highly efficient motor to drive the spindle and a low-inertia spindle.

The structure of the spindle covering has been enhanced to reduce air purge. Air blast operations have also been reviewed to optimize the air discharge timing. These improvements have greatly reduced air consumption.

Measures for chips based on Brother's accumulated expertise, fully demonstrates their effects on high-speed and highly efficient machining.

Discharge pressure and flow has been increased to efficiently remove chips attached to the holder.

A filter clog warning function has been added.

A Z-axis metal slid cover is used, eliminating damage to the cover due to chips. This prevents direct splashing of coolant and reduces the influence of thermal distortion.

Usability has been enhanced to minimize incorrect operations or entries.

Various user-friendly functions have been prepared to make operation much easier.

User-friendly screen configuration, including graphic drawing, menu screens for program creation, alarm recovery screens, etc.

In addition to the function to improve the shape, a smoothing function to improve the surface quality has been added to enable more accurate finishing. Minute block processing capability has also been greatly improved to ensure high-speed and highly accurate shape machining.

The column does not protrude into the machining room and there are no cables to the table. Designing the tools to be loaded is easy.

|

|

|

|---|---|---|

| TC-S2DN/-O/-S | TC-22B/TC-22B-O | TC-20B |

|

|

|

|

|

|

|

|---|---|---|

| TC-R2B | TC-32BN QT/FT | TC-31B |

|

|

|

|